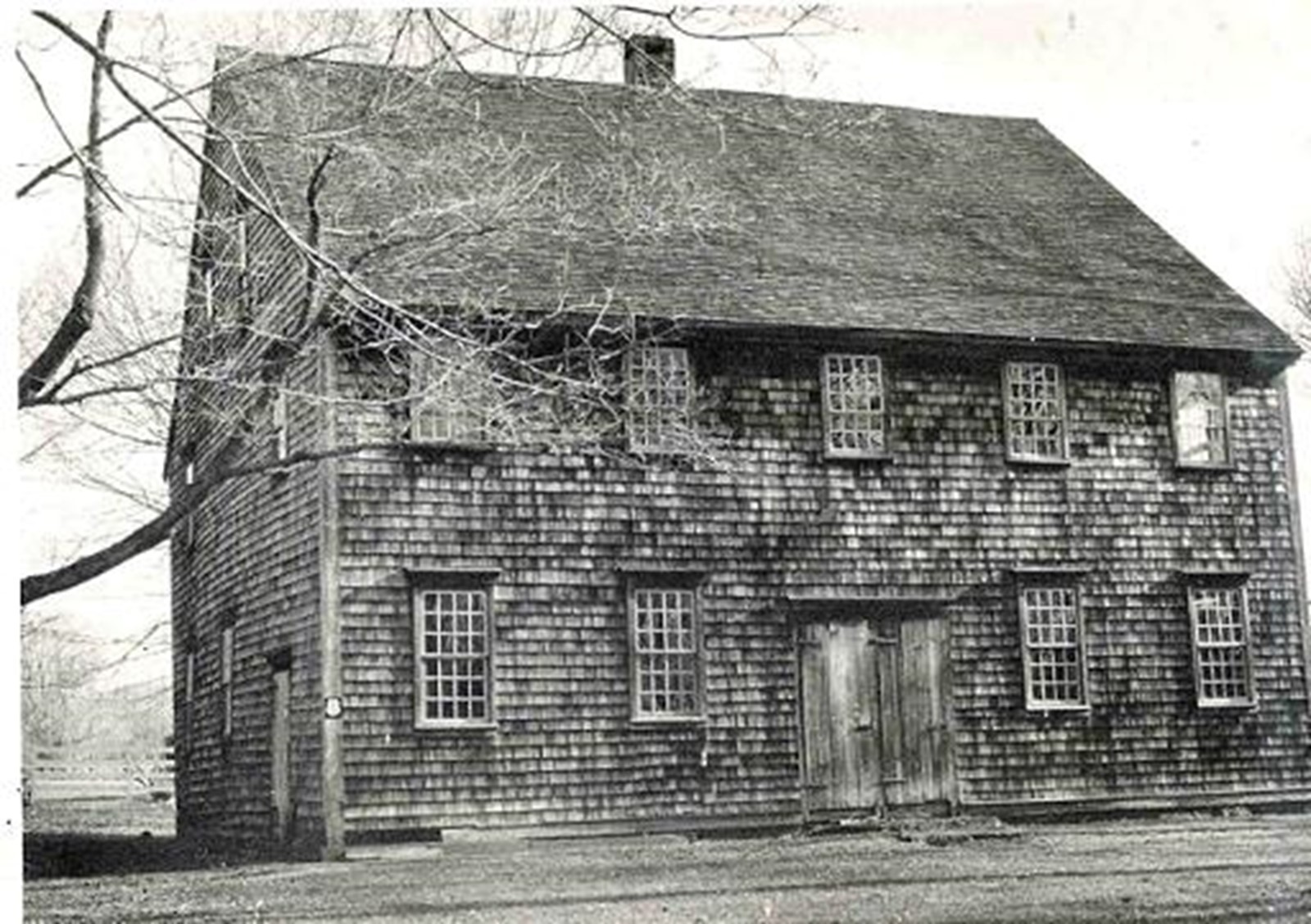

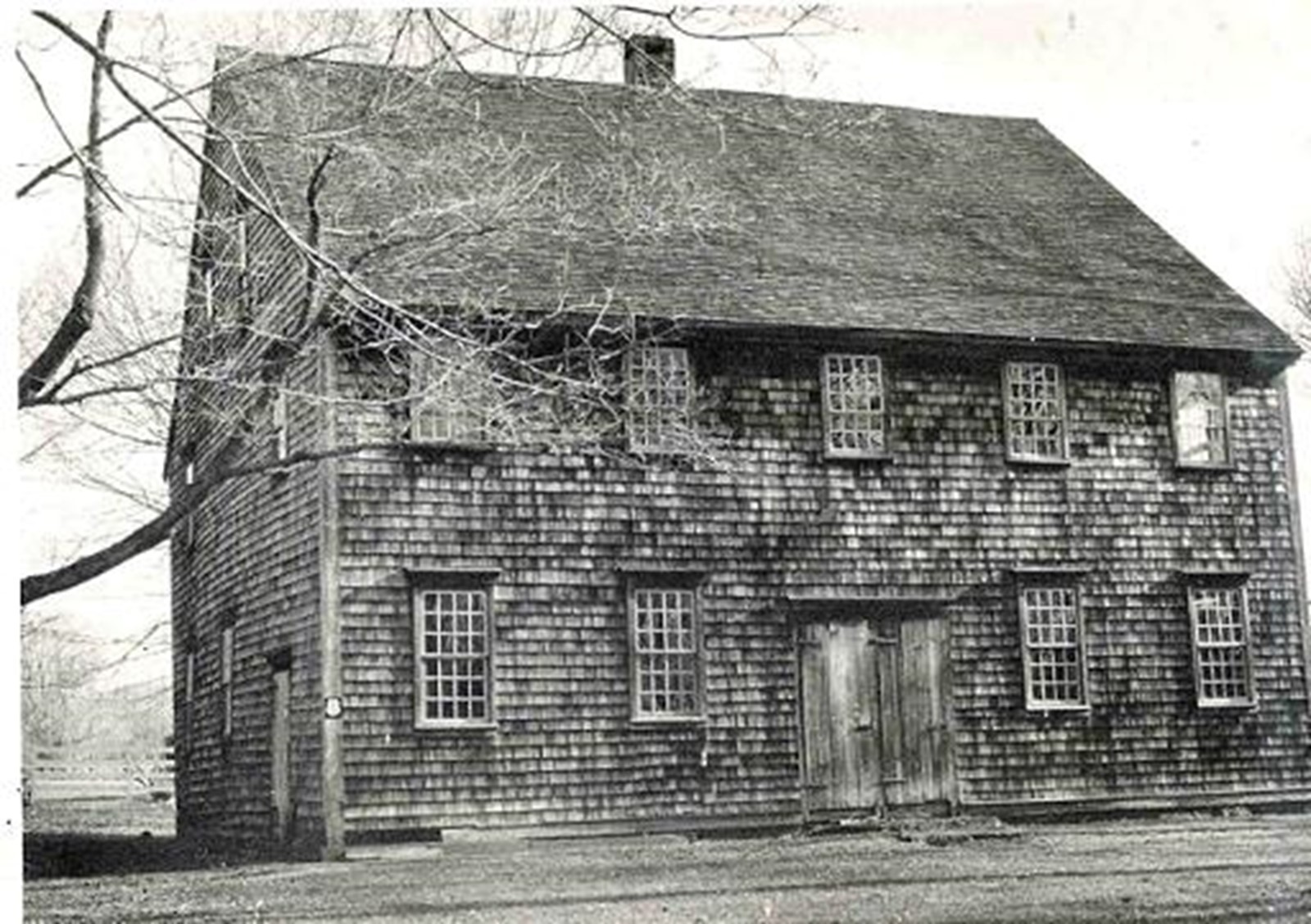

Early in Hudson Valley Preservation’s history, one project stood out as especially meaningful: the restoration of the Oblong Quaker Meeting House in Pawling, New York.

Built in 1764, this meeting house has been part of the Quaker Hill community for more than two centuries. Over the years, it served not only as a place for gathering and worship, but also as a site of unexpected importance during the Revolutionary War, when it was used to care for officers in General Washington’s army.

By the early 1990s, the building was showing clear signs of age. The foundation had weakened significantly, parts of the structure were beginning to fail, and the roof shingles had become brittle from years of exposure. The windows, too, were in rough shape, with warped frames and missing panes.

In 1993, the Quaker Hill and Pawling Historical Society brought HVP on to help stabilize and restore the meeting house through a multi-phase effort. Roberta Linkletter, who was serving as President of the Historical Society at the time, played an important role in guiding the project and helping ensure the meeting house could be preserved for future generations.

The work began with lifting the building and reconstructing the foundation entirely. Once the crawl space was cleared of damaged timbers, a new concrete foundation was poured. Dry-laid stone was then installed above grade to preserve the historic look of the original foundation.

The restoration continued with major structural repairs on the first floor, including replacement of large framing members. A rebuilt chimney and new wood shingle roof followed, returning strength and protection to the building.

Don Carpentier, founder of Eastfield Village and a respected voice in traditional building practices, was also involved as a partner during the project. His expertise helped shape key elements of the scope, planning, and overall approach to the work. More information about Don’s legacy can be found here: https://www.historiceastfield.org/history.

Looking back, we didn’t fully realize it at the time, but the collaboration between HVP, Roberta as the owners’ representative, and Don as a preservation expert became a model for the way we like to develop projects. That kind of partnership, between owners, designers, builders, and craftspeople, creates the strongest outcomes in restoration and remains central to our philosophy today.

A later phase of restoration, completed in 2007, focused on exterior details, including restoring the window sashes and replacing sections of wood shingle siding and trim.

Today, the Oblong Quaker Meeting House remains a powerful example of what thoughtful preservation can achieve. Projects like this helped define HVP’s early direction and continue to reflect our commitment to protecting the historic buildings that shape the character and stories of our region.